You're

at Overcoring

The overcored

specimen is inserted into the biaxial pressure cell to measure

Young's modulus based on the thick-walled cylinder solution.

Poisson's ratio is usually assumed to be known for a specific

rock or measured in the laboratory using an extracted EX-size

core.

|

Overcoring

methods

Overcoring

methods are measuring in situ stress based on the stress relief

around the borehole. The relief of external forces by overcoring

causes the changes in

- borehole

diameter for "USBM deformation gage";

- strain

on the borehole wall for "Triaxial strain cell",

or

- changes

in strain on the flat end of the borehole for "Doorstopper".

If the

elastic properties of the rock are known, the changes in borehole

diameter or strains can be converted to in situ stress in

the rock.

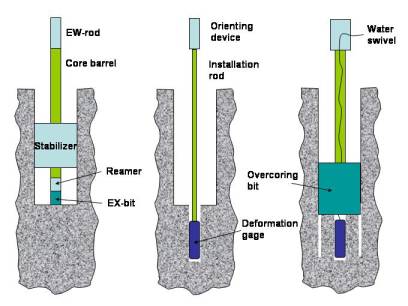

USBM

deformation gage - method

The USBM

three-component borehole deformation gage is designed to measure

diametral deformations of an EX-size (1.5" in diameter)

borehole during overcoring a concentric borehole (6"

in diameter). The diametral deformations are measured in three

directions (60 degree apart) in the same diametral plane.

The field

procedures consist of drilling a concentric EX-size borehole,

installation of the deformation gage, and overcoring a stress

relief borehole.

Click the above picture to get the full size drawing.

USBM

deformation gage - instrument

The

borehole deformation gage consists of six strain-gaged cantilever

transducers made out of heat-treated beryllium copper. At

the free end of each cantilever, tungsten carbide button is

mounted to make a contact with the borehole wall. A pair of

transducers, placed 180 degree apart, measure diametral deformation

of the borehole.

USBM Deformation gage

USBM

deformation gage - theory

If

the borehole is oriented in 0y direction and the xz plane

is perpendicular to the borehole, the diametral deformation

Dd at q

(angle measured counterclockwise from 0x oriented with the

a pair of buttons) can be represented as follows based on

the theory of elasticity and the Kirsch solution.

The

diametral deformations DD at q=0,

60, and 120 are measured from field testing. Young's modulus

E and Poisson's ratio n are measured

from the extracted core. If the stress component, sy,

parallel to the borehole is known (usually assumed to be zero

for shallow measurements), the stress components in xz plane

can be calculated as follows.

Three channels of diametral deformations logged continuously

as the deformation gage is overcored. As the overcoring bit

passes through the plane of measurements the stresses are

relieved and the results are shown as diametral deformations

(After Fisher, 1982).

|

|

|

|

Hooker,

V.E. and D.L. Bickel, Overcoring equipment and techniques

used in rock stress determination, USBR IC-8618 (1974).

Hooker,V.E,

Aggson, J.R., and D.L. Bickel (with appendix by W.I.

Duvall), Improvements in the three-component borehole

deformation gage and overcoring technique, USBR RI-7894

(1974).

Fischer,

D.J, Near surface stress measurements in a candidate

rock mass for superconductive magnetic energy storage,

MS Thesis, University of Wisconsin-Madison (1982).

Goodman,

R.E., Introduction to rock mechanics, 2nd edition, John

Wiley and Sons (1989).

USBM-RI9582

|

|